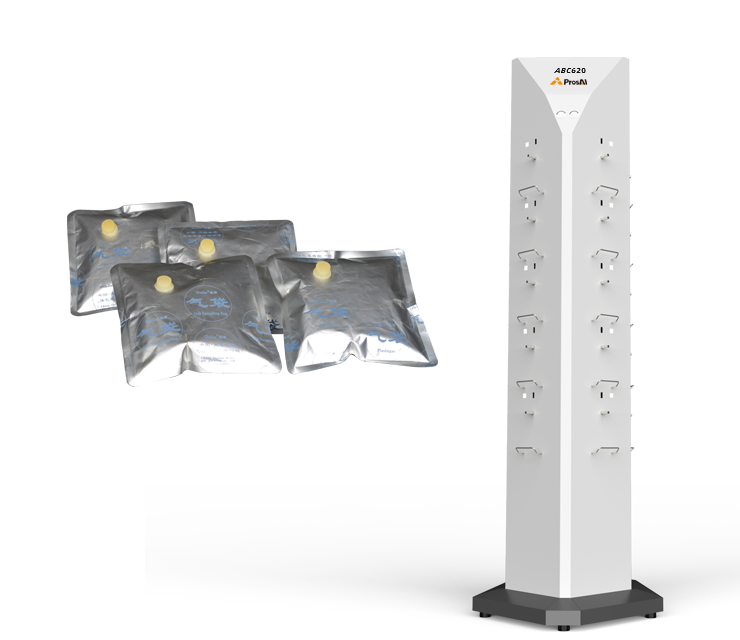

Air bag cleaning machine ABC620

★High-efficiency air bag automatic cleaning ★20 bits ★Automatic temperature control ★Automatic pressure control

Product Presentation

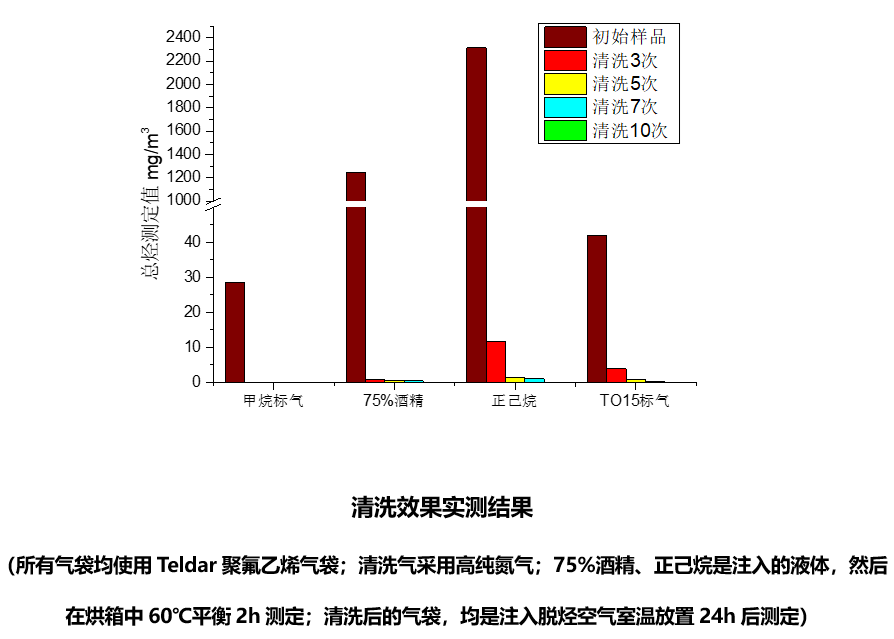

At present, air bags are basically cleaned manually, requiring experimenters to inject high-purity nitrogen into each air bag and then extract it. This is repeated many times. This method not only consumes the time and energy of the experimenter, but also in the face of air bags that have collected too high concentration samples, it is often the case that the cleaning is not clean and the measurement results are affected. Faced with this kind of high-residue air bag, even heating and cleaning are required, which is more labor-intensive and time-consuming. ABC620 can automatically clean up to 20 air bags at the same time, and the user only needs to load and unload the air bags (convenient quick-plug). It liberates experimental personnel, solves the pain points of experimental efficiency, and can be used as a supporting equipment for VOCs solutions. Meet the following standards:

Product Features

Fully inert gas path, with cleaning gas heating function, flow path heating function and air bag heating function to ensure clean cleaning and no residue. Meet the quality control requirements for air bag cleaning in the standard (HJ 38-2017, etc.). The user only needs to load and unload the air bag and one-button start, no other operations are required. The curing method is simple, efficient and practical: ABC620 air bag leak detection prompt can promptly indicate whether the air bag is leaking; the pressure of the air bag is automatically controlled to prevent the air bag from bursting. Intelligent heating and temperature control. The running status of the instrument can be observed at any time through the status light.

Application Fields